Effective branding requires a unique logo to emblazon on your products and labels. To put your logo on these objects you’ll need special equipment, a machine that cuts out your designs. This equipment is called a die-cutting machine, and with its help, you can design and cut the label of your choice from a variety of materials.

But how does this process work? What should you keep in mind when designing labels?

The Die Cut Process

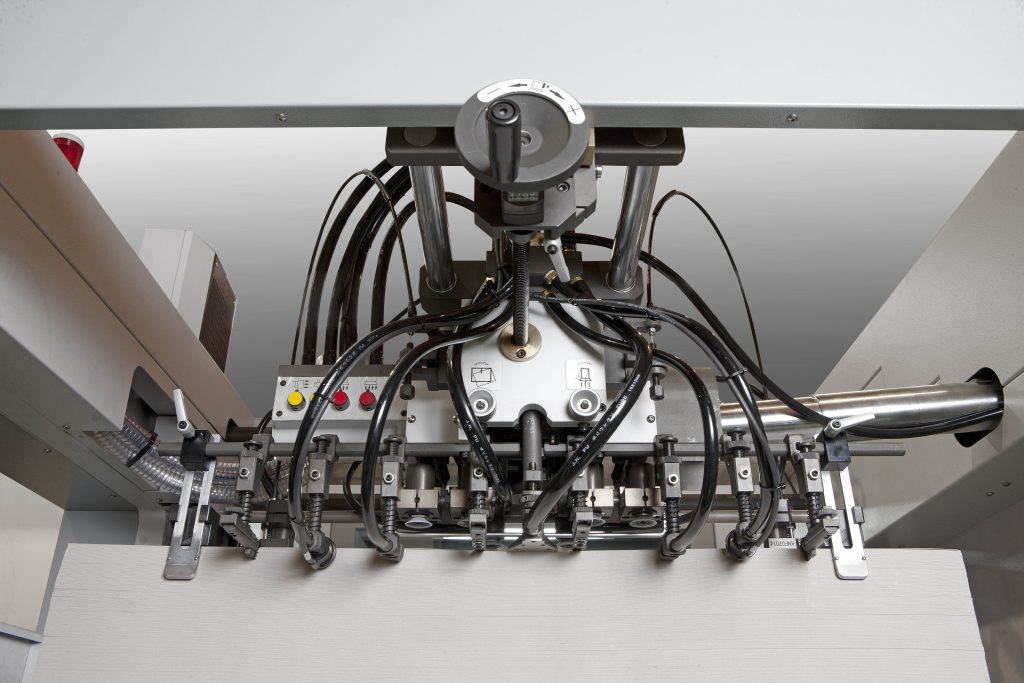

Die-cutting is used in printing to manufacture custom designs for your labels. It’s part of the finishing stage of label creation. Although there are many types of die-cutting machines, they all operate on the same basic principle.

Simply put, a die is a very sharp, thin piece of metal in a specific shape. This metallic shape is then attached to a base that is in turn installed in a printing press. Like an enormous cookie cutter, the die cutter stamps down on the material being fed through the press, cutting it in the shape of the metal. These machines can cut out designs on paper, cardboard, fabric, and even metals.

Tips for Creating a Die Cut Label

Die-cutting machines are often used to print out labels. Most die-cutting equipment can easily make labels in basic geometric shapes, like squares, rectangles, and circles. Even though die-cutting machinery is versatile, there are still limits to what they can do.

Keep the following tips in mind when designing a label for easy fabrication through die cutting machinery.

- When creating the base design for your label, you must add a bleed area around it to prevent white spaces. This bleed area should go beyond the edge of your design by at least 1/16th of an inch.

- No matter what software you’re using to make your label design, correctly identify which lines the die machine should cut and which lines are purely illustrative.

- Don’t incorporate designs with sharp corners or acute angles. These types of cuts can tear your material when the labels are removed after they’ve gone through the die cutter.

- Should your label have holes in its design, remember to leave just enough space between the hole and the edge of the label. This way, you can avoid tearing the material when removing the label.

No matter how beautifully you design your label, you still risk wasting the effort and resources if you manufacture it using unreliable machinery. The only way to avoid this risk is to ensure you acquire your die-cutting equipment from a reliable manufacturer. With such a business on your side, you can be confident that your packaging and labelling process will yield your desired results.

Work with a Reliable Manufacturer

SBL Machinery has been a reliable manufacturer of various printing packaging machinery for more than 50 years. Since we first began operations in 1968, SBL Machinery has manufactured equipment such as high-speed folding machines and die-cutting equipment that businesses can trust.

We’ve worked with companies from all over the world, from the Americas to Europe and Asia, helping them build their futures one machine at a time.

Fill out our contact form today and start a partnership with a manufacturer you can rely on.

Related Posts

如何採購合適軋盒機?|軋盒機客戶最常後悔的4件事(採購指南)

一來幫助大家選擇更合適於自身需求軋盒機,二來協助各位採購軋盒機時避免掉進陷阱或是陷入迷思。深信倘若採購前有先參考過以下4件事的話,可以大幅減少大家走冤枉路的機率。

10項機械製造商不會透露的評選指標【下】

上個月推出10項機械製造商不會透露的評選指標(上)後,已經收到許多如雪片飛來好評及回應,直接來看10項機械製造商不會透露的評選指標(下)內容吧!

10項機械製造商不會透露的評選指標【上】

10項評選指標均相當具有參考價值,可能部份指標是公司或採購決策單位壓根從未考量或思維角度。希望透過本篇文章,讓大家在評選機械製造商時有更多可參考指標及方向。