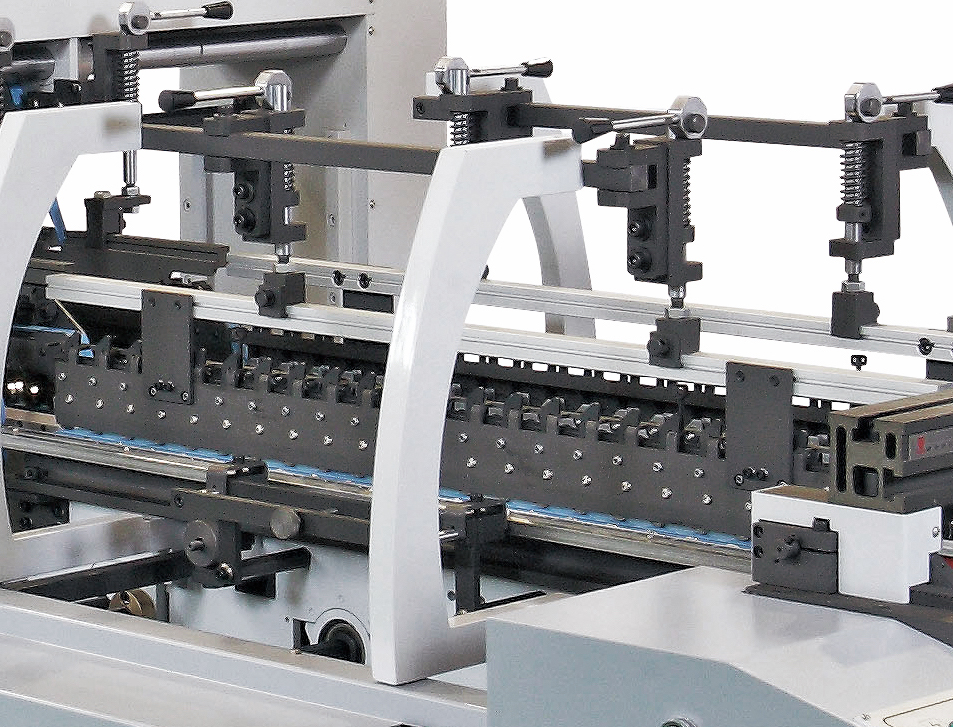

Modern print finishing equipment is built to withstand continuous and long-term use. We at SBL, for example, manufacture folder gluer machines using high-quality materials from Taiwan, Japan, and the EU. We also integrate high-tech software, electrical components, and other features to expand the uses of our products and equip them for massive manufacturing demands.

Wear and tear, however, are inevitable over time. Premium-quality parts still eventually deteriorate and function at a sub-optimal rate. It is during this period that owners need to be more observant of their equipment and keep an eye out for signs that their machines need repairs or parts need replacing.

As the manufacturer of your folder gluer machines, SBL can provide servicing assistance. Things like geographic distance and logistics, however, could make it difficult for our technicians to reach your facility.

Common Problems and Troubleshooting Tips

Here are some of the issues you might encounter with a folding and gluing machine over time:

Inaccurate folds, gaps, and creases in the wrong positions

There are several possibilities for these flaws. The composition of the paper or cardboard itself could be the issue or the finish applied on the surface of the material. Test the machine again using a different substrate. If the problems persist, examine the upstream SOPs: there could be flaws in the practices, such as overloading or underloading the feeder tray. Another possibility is that the conveyor belts may be worn out or misaligned. Either situation would require a complete stop of your operations to make way for repairs and replacement.

Slow or inconsistent speed

We manufacture folding and gluing machines that can last decades. They can only realize this potential, however, if they are well maintained and cared for. Irregularities in the production speed mean it’s time for a maintenance check (and to look for underlying issues).

Weak adhesive

This is usually a glue quality issue that can be corrected by switching to something with stronger adhesive strength or increasing the amount the gluer applies. Alternatively, you can install a grinding device as reinforcement for the gluing section.

Paper jams

This is another problem with many possible causes. Paper jams often happen inside the machine as the paper or cardboard moves from one section to the next. This could be the result when the substrate’s dimensions are too big or too small, the conveyors are misaligned, or the lower fold plates are even just slightly off their correct positions. To troubleshoot the latter two, SBL can provide instructional references for your on-site technicians to follow.

Persistent paper jams could also mean hardware damage, specifically a bent fold plate deflector. Get in touch with SBL immediately if this is the problem: we can ship a replacement part your way as quickly as possible.

Curling edges

Thin paper substrates can sometimes curl after rapid passes through rollers and fold plates. Consistent curls can be remedied by slightly widening the gap of the feeding lip or installing smoothers and guides (the latter ensures the paper moves through the machine at the correct position. It gets trickier to manage curling, however, when sheets emerge with curls in different locations. One cause could be the direction of the folds goes against the grain of the paper or cardboard. You can flip the sheets or turn the stack in the feeder station so that the folds are parallel with the grain.

Two or more sheets enter the feeder at once

When you run the folder-gluer machine continuously and at a high speed, sheets might stick together in the feeder tray and enter the machine two or more at a time. At the very least, you’ll have a handful of defective boxes; at worst, your production will lag because of paper jams. Machine operators can prevent this by manually fanning the edges of the sheets with a thumb. This is a band-aid solution, however, and inefficient when you have multiple machines to look after. Fortunately, SBL offers optional features like a suction device to improve the feeder’s performance.

Support Services by SBL

If you think your machine needs in-depth diagnosis and servicing, fill out our Service Form. Our service team will get back to you as quickly as possible and give more details about your service request.

The sooner you get in touch, the quicker we can solve the problems in your equipment. Contact us today.

Related Posts

如何採購合適軋盒機?|軋盒機客戶最常後悔的4件事(採購指南)

一來幫助大家選擇更合適於自身需求軋盒機,二來協助各位採購軋盒機時避免掉進陷阱或是陷入迷思。深信倘若採購前有先參考過以下4件事的話,可以大幅減少大家走冤枉路的機率。

10項機械製造商不會透露的評選指標【下】

上個月推出10項機械製造商不會透露的評選指標(上)後,已經收到許多如雪片飛來好評及回應,直接來看10項機械製造商不會透露的評選指標(下)內容吧!

10項機械製造商不會透露的評選指標【上】

10項評選指標均相當具有參考價值,可能部份指標是公司或採購決策單位壓根從未考量或思維角度。希望透過本篇文章,讓大家在評選機械製造商時有更多可參考指標及方向。